Add to Cart

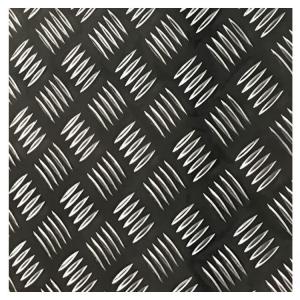

2mm 3mm 3003 5 bars Customized Aluminium Checker Plate For Anti-skidding Flooring

Production Description

Aluminum Checker Sheet Advantages

1. Accurate size, good anti-slip effect,wide range of applications .

2. Strong plasticity, easy forming and excellent processing performance.

3. Embossed aluminum sheet can form a dense and strong oxide film on aluminum surface to prevent the intrusion of oxygen, so it has good corrosion resistance.

4. Good elongation and tensile strength, fully able to meet the normal processing requirements (stamping, stretching), high formability.

5. The surface quality of aluminum checker plate is good, no oil spots, waves, scratches, roller marks, neat trimming, no burrs.

6.The advantages of tread plate are slip resistant, corrosion resistant, hygienic, protective and attractive.

7.Tread plate can be found in parking lots, garages, stairways, step ladders, elevators, loading docks, warehouses, distribution centers, hospitals, factories, ships, floating docks, refrigerator trucks, walk-in freezers, elevators, walkways, handicapped access ramps, truck tool boxes, trailers, and much more.

| Diamond Aluminium Plate | |||||||||

| Alloy | 1050/1060/1100/3003/5754/5083/6061/6063/6060/6082/8011 | ||||||||

| Temper | H14,H18,H24,H32 ,H112, H114, T4,T6 ,T651,O | ||||||||

| Thickness (mm) | 0.4mm to 7 mm | ||||||||

| Width (mm) | Up to 1800mm | ||||||||

| Length (mm) | Up to 6000mm | ||||||||

| Standard | GB/T3880-2012 | ||||||||

| MOQ | 5ton | ||||||||

| Application | 1)Decorated inside and outside the car /building frame, windows, doors, ceiling, decorating panel and curtain wall | ||||||||

| 2)Household appliances: refrigerators, microwave ovens, audio equipment, etc. | |||||||||

| ALLOY | CHEMICAL COMPOSITION (%) | |||||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Other | Al | |||

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | 0.05 | 0.15 | rest | ||||||

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | __ | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 3104 | 0.6 | 0.8 | 0.05-0.25 | 0.8-1.4 | 0.8-1.3 | __ | __ | 0.25 | 0.1 | __ | 0.05 | 0.15 | rest | |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.2 | __ | 0.4 | 0.1 | __ | 0.05 | 0.15 | rest | |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | __ | 0.1 | __ | __ | 0.05 | 0.15 | rest | |

| 5A06 | ≤0.40 | 0.000~0.400 | ≤0.10 | 0.50~0.8 | 5.8~6.8 | __ | 0.0001~0.005 | ≤0.20 | 0.02~0.10 | __ | 0.05 | 0.1 | rest | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.1 | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 5050 | 0.4 | 0.7 | 0.2 | 0.1 | 1.1-1.8 | 0.1 | __ | 0.25 | __ | __ | 0.05 | 0.15 | rest | |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | 0.25 | 0.2 | 0.05 | 0.15 | rest | |||

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | __ | 0.2 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.2 | 0.25 | 0.2 | 0.05 | 0.15 | rest | |||

| 5182 | 0.2 | 0.35 | 0.15 | 0.2-0.5 | 4.0-5.0 | 0.1 | 0.25 | 0.1 | 0.05 | 0.15 | rest | |||

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | _ | 0.25 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 5086 | 0.4 | 0.5 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | rest | |||

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | 0.05 | 0.15 | 0.1 | 0.05 | 0.15 | rest | |||

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | __ | 0.25 | 0.15 | __ | 0.05 | 0.15 | rest | |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | __ | 0.1 | 0.1 | __ | 0.05 | 0.15 | rest | |

Technical Property

| Alloy | Temper | Thickness(mm) | Tensile strength(Mpa) | Yeild strength(Mpa) | Elongation(%) |

| Min | |||||

| 3003 | O H111 | >0. 20—0. 50 | 95-135 | 35 | 15 |

| >0. 50 — 1. 50 | 17 | ||||

| >1. 50 — 3. 00 | 20 | ||||

| >3.00 — 6. 00 | 23 | ||||

| >6.0-12.5 | 24 | ||||

| >12.5-50 | |||||

| H12 | >0. 20—0. 50 | 120-160 | 90 | 3 | |

| >0. 50 — 1. 50 | 4 | ||||

| >1.50 — 3.00 | 5 | ||||

| >3. 00 — 6. 00 | 6 | ||||

| H14 | >0. 20 — 0. 50 | 145-195 | 125 | 2 | |

| >0. 5- 50 | 2 | ||||

| >1. 50 — 3. 00 | 3 | ||||

| >3. 00—6.0 | 4 | ||||

| H16 | >0. 20 — 0. 50 | 170-210 | 140 | 2 | |

| >0.50 — 1.50 | 3 | ||||

| >1. 50—4. 00 | 3 | ||||

| H18 | >0. 20 — 0. 50 | 190 | 170 | 1 | |

| >0. 50—1. 50 | 2 | ||||

| >1. 50 — 3. 00 | 2 | ||||

| H22 | >0. 20—0. 50 | 120-160 | 80 | 6 | |

| >0. 50 — 1.50 | 7 | ||||

| >1.50 — 3.00 | 8 | ||||

| >3. 0—6.0 | 9 | ||||

| H24 | >0. 20—0. 50 | 145-195 | 115 | 4 | |

| >0. 50 — 1.50 | 4 | ||||

| >1.50 —3. 00 | 5 | ||||

| H26 | >0. 20 — 0. 50 | 170-210 | 140 | 2 | |

| >0.50—1.50 | 3 | ||||

| >1.50 — 3. 00 | 3 | ||||

| H28 | >0,20 — 0,50 | 190 | 160 | 2 | |

| >0. 50〜L 50 | 2 | ||||

| >1. 50—3. 00 | 3 | ||||

Photos

Company Introduction

| Equipment Production Parameters By Chongqing Dongchong Aluminum Co.,Ltd | |||||||

| 1650mm Slitting machine | Uncoil(MM) | Finished size(MM) | Slitting Width(MM) | ||||

| ID | OD | Width | Thickness | ID | OD | Above 0.5mm≥ 20mm | |

| Φ 400 | ≤ 1800 | ≤ 1600 | 0.5-4.5 | Φ 400 | ≤ 1700(normal) | ||

| Φ 500 | Φ500(normal) | ||||||

| Φ 600 | |||||||

| 650mm Slitting machine | Uncoil(MM) | Finished size(MM) | |||||

| ID | OD | Width | Thickness | ID | OD | Width | |

| Φ 400 | ≤ 1780 | ≤ 600 | 0.1-1.5 | Φ150 Φ500 | ≤ 1700(normal) | 6-600 | |

|

Product Tags:

Inquiry Cart

0

| |||||||